| Availability: | |

|---|---|

| Quantity: | |

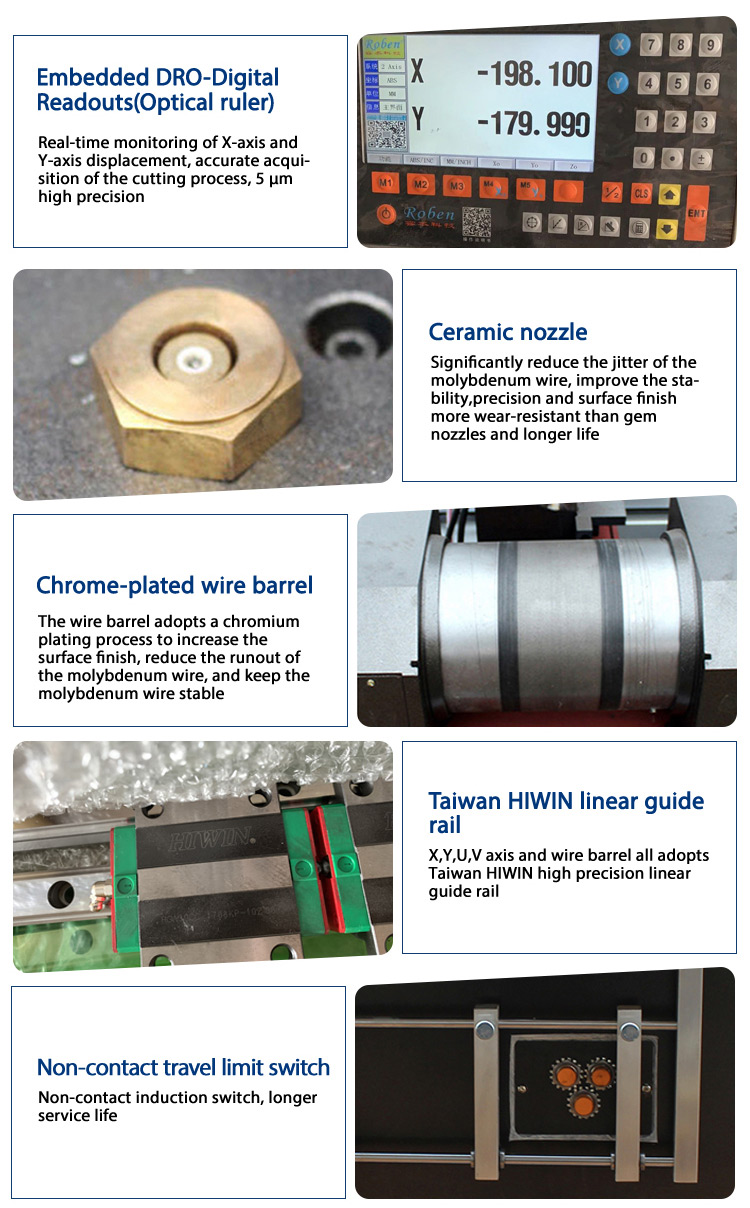

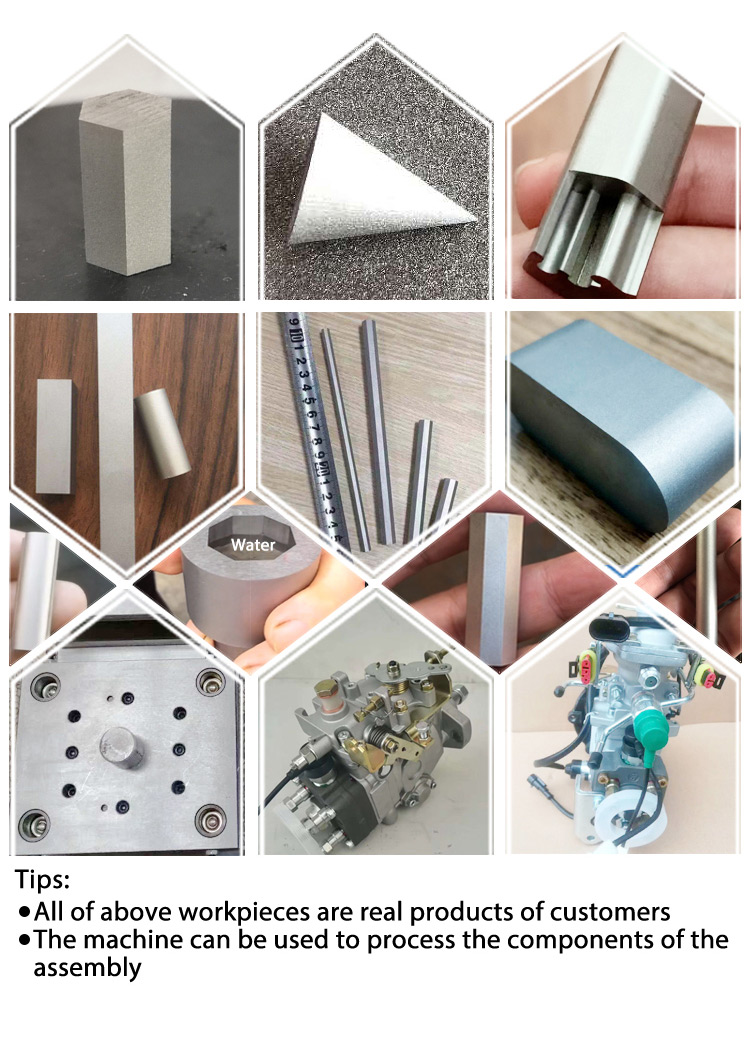

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Terui CNC Machine Co.,Ltd. has continuously improved our TRS series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price.

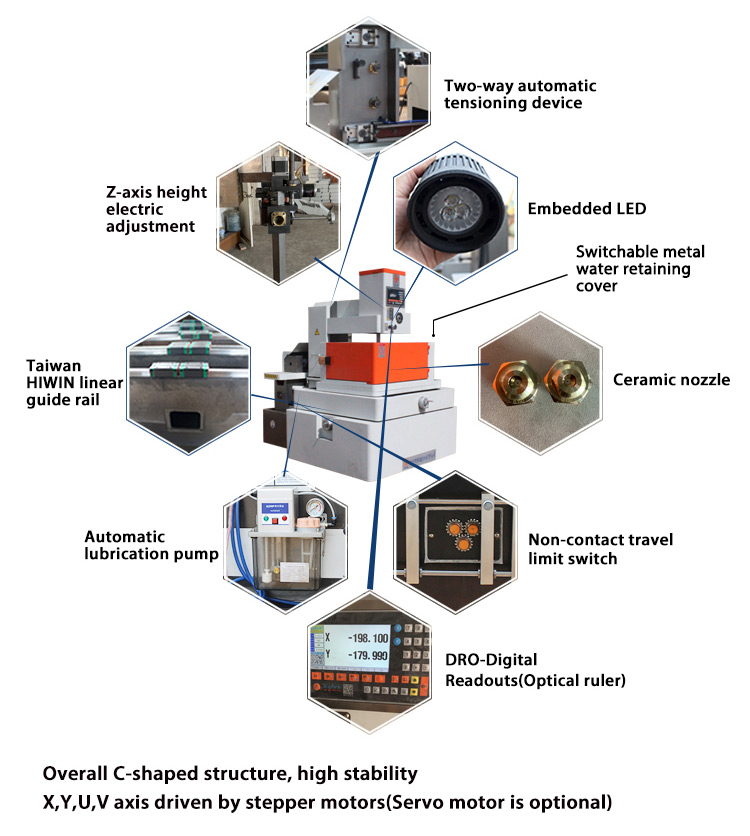

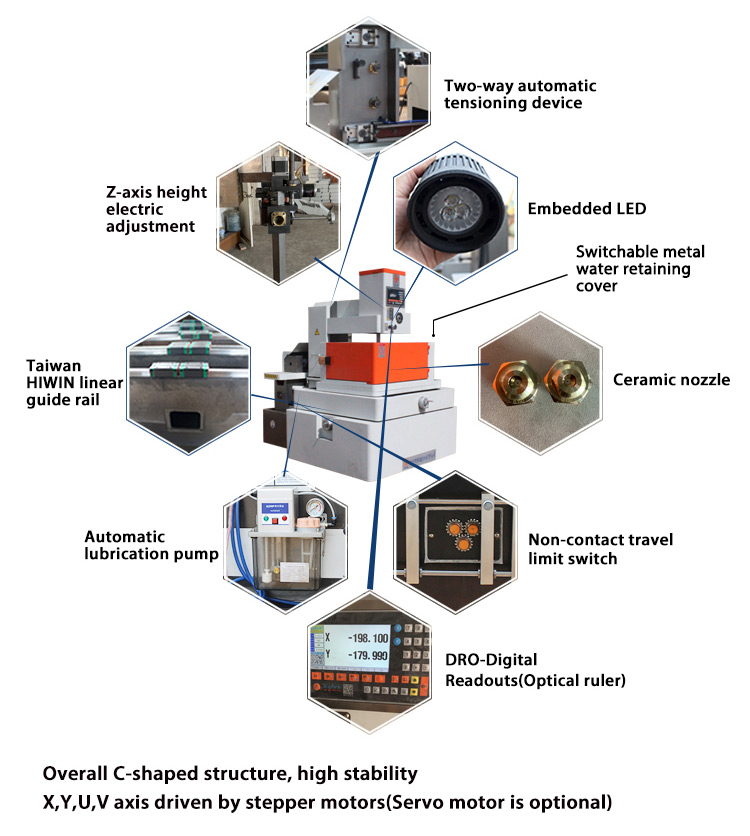

● Imitating the slow-walking model, the appearance is exquisite, the host is aC type structure with good rigidity, and the casting is made by a well-known manufacturer.

● Strong and stable.

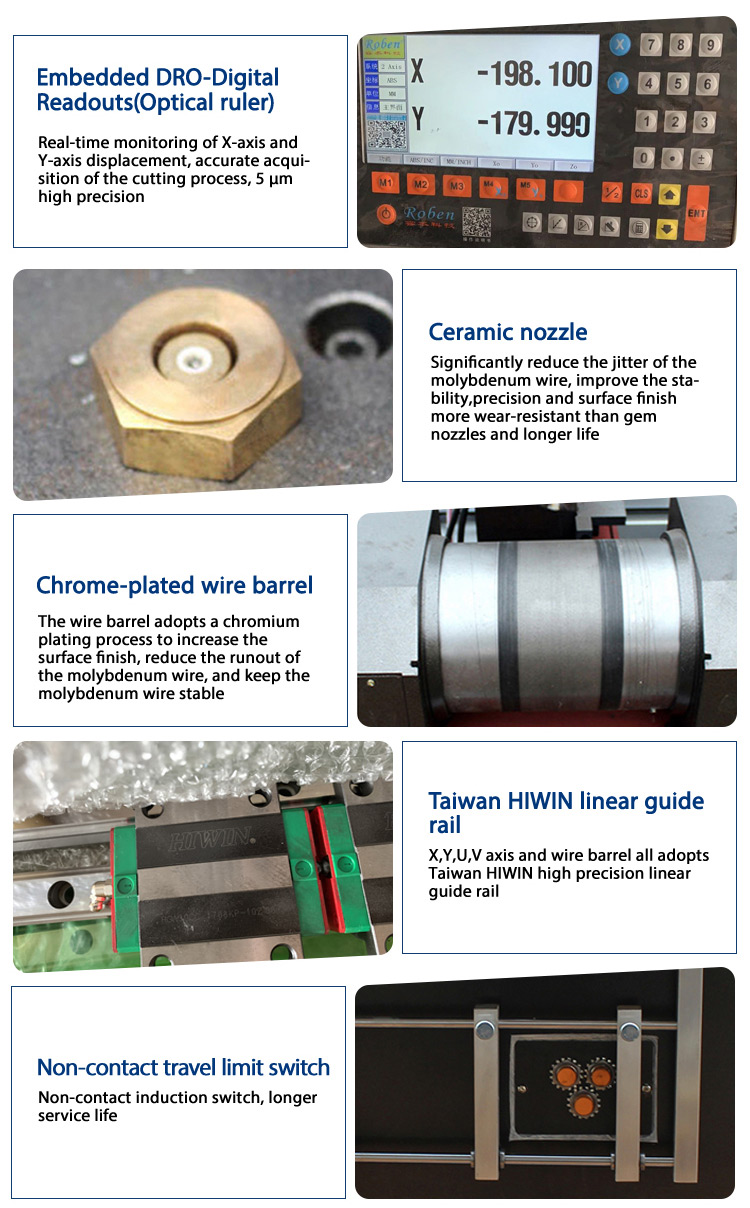

● Taiwan linear guide rails have very good sealing and stability, ensuring the long-term stability of the whole machine.

● Lead screw adopts famous brand precision lead screw.

● The unique two-way tight wire constant tension structure ensures that the molybdenum wire runs smoothly and the tension is uniform and stable.

● Specially stabilizing wire device, well-known brand water nozzle can not only stabilize the wire well, but also solve the problem of difficult threading.

● Timing automatic refueling device, simple maintenance, maintenance in place.

● The spindle is automatically raised and lowered to improve production efficiency and ensure mechanical quality.

● Well-known brand guide wheels: ensure smooth wire transport and long life.

● Optional large taper swinging device, which not only guarantees the requirements of large taper accuracy, but also guarantees the straight effect.

● High standard installation, high-precision instrument detection(such as laser interferometer) to ensure positioning accuracy,vertical positioning accuracy, parallelism, verticality of the guide rail, etc. fully meet national standards.

| Model | Company | TRS32 |

| Table travel | mm | 320╳400 |

| Maximum cutting thickness | mm | 380 |

| Maximum cutting taper | mm | 6°-12°/80 |

| Bearing capacity | kg | 300 |

| Machine weight | kg | 1400 |

| Machine tool dimensions | mm | 1240╳1170╳1400 |

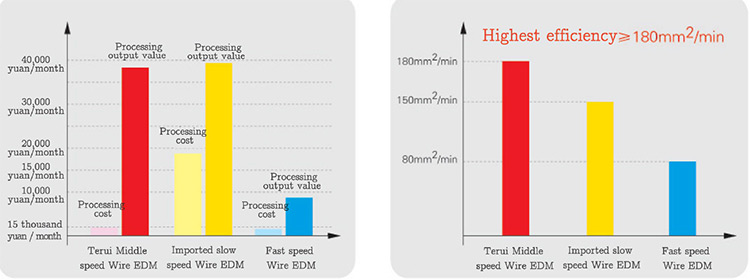

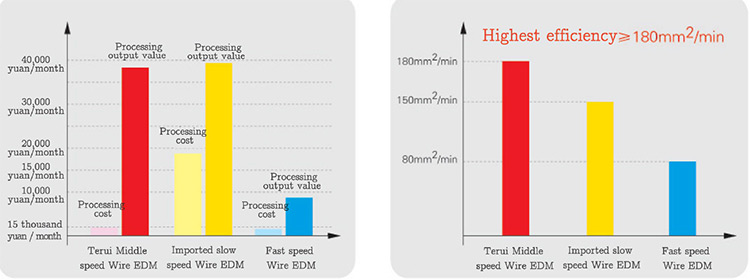

| Maximum processing speed | m㎡/min | ≥160 |

| Machined surface roughness | μm | ≤Ra1.2 |

| Machining accuracy | mm | ≤0.01mm |

P3 screw |

HIWIN linear guide |

Automatic refueling device |

Because brass wire cutting machine tools are expensive and difficult to learn, Taizhou Terui CNC Machine Co.,Ltd. has continuously improved our TRS series machines based on the strengths of hundreds of the companies,which is with simple operation,long service life and high cost performance. Molybdenum wire can be reused instead of disposable brass wire.Not only greatly reduces the cost of buying machines and processing for customers, but also provides customers with excellent cutting prcision and finish. The machine parts all come from high-end brands (HIWIN linear guide rail, Japan NSK bearings, Military grade P3 double nut ball screw, Japan Panasonic servo system, etc.) to ensure good machine performance, and at the same time,we still provide customers with reasonable price.

● Imitating the slow-walking model, the appearance is exquisite, the host is aC type structure with good rigidity, and the casting is made by a well-known manufacturer.

● Strong and stable.

● Taiwan linear guide rails have very good sealing and stability, ensuring the long-term stability of the whole machine.

● Lead screw adopts famous brand precision lead screw.

● The unique two-way tight wire constant tension structure ensures that the molybdenum wire runs smoothly and the tension is uniform and stable.

● Specially stabilizing wire device, well-known brand water nozzle can not only stabilize the wire well, but also solve the problem of difficult threading.

● Timing automatic refueling device, simple maintenance, maintenance in place.

● The spindle is automatically raised and lowered to improve production efficiency and ensure mechanical quality.

● Well-known brand guide wheels: ensure smooth wire transport and long life.

● Optional large taper swinging device, which not only guarantees the requirements of large taper accuracy, but also guarantees the straight effect.

● High standard installation, high-precision instrument detection(such as laser interferometer) to ensure positioning accuracy,vertical positioning accuracy, parallelism, verticality of the guide rail, etc. fully meet national standards.

| Model | Company | TRS32 |

| Table travel | mm | 320╳400 |

| Maximum cutting thickness | mm | 380 |

| Maximum cutting taper | mm | 6°-12°/80 |

| Bearing capacity | kg | 300 |

| Machine weight | kg | 1400 |

| Machine tool dimensions | mm | 1240╳1170╳1400 |

| Maximum processing speed | m㎡/min | ≥160 |

| Machined surface roughness | μm | ≤Ra1.2 |

| Machining accuracy | mm | ≤0.01mm |

P3 screw |

HIWIN linear guide |

Automatic refueling device |