| Availability: | |

|---|---|

| Quantity: | |

Taizhou Terui CNC Machine Co., Ltd. produces whole series of DK77 CNC EDM wire cutting machines, which adopts high precision V-shaped guide rail (Linear guide rail optional) and P3-grade high precision ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs, like non-standard models DK7740(45)F, DK7750(55)F, DK7763F, DK7780F, DK77100F, DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed EDM wire cutting machines (Precision ≤ ±0.005mm, roughness ≤ 1.0μm).

The following are the main parameters of DK77 series machines.

1、Standard maximum cutting taper:±6°/80mm; (±15°, ±30°, ±45° are optional)

2、Precision ≤ 0.02mm, according to GB7926-2005 standard; (If linear guide equipped, the precision can reach 0.01mm)

3、Best surface roughness ≤ Ra2.5μm (single-cut), Ra1.5μm (multi-cut);

4、Molybdenum wire diameter: 0.1-0.2mm;

5、Max. cutting speed ≥ 120mm^2/min;

6、Voltage: 3 phase 380V (single phase 220V, 3 phase 220V or other voltage can be customized), Power: 1.5KW;

7、Working fluid: Water-based emulsion.

Please go to high-speed-wire-edm.html to check the detailed model info. OR feel free to contact us to get a solution or quotation by email, WhatsApp or phone.

Email: daley@teruimachine.com, jack@teruimachine.com

Mobile/WhatsApp: +86 158 5087 0508, +86 173 1566 7380

Tel: +86-523-86816601

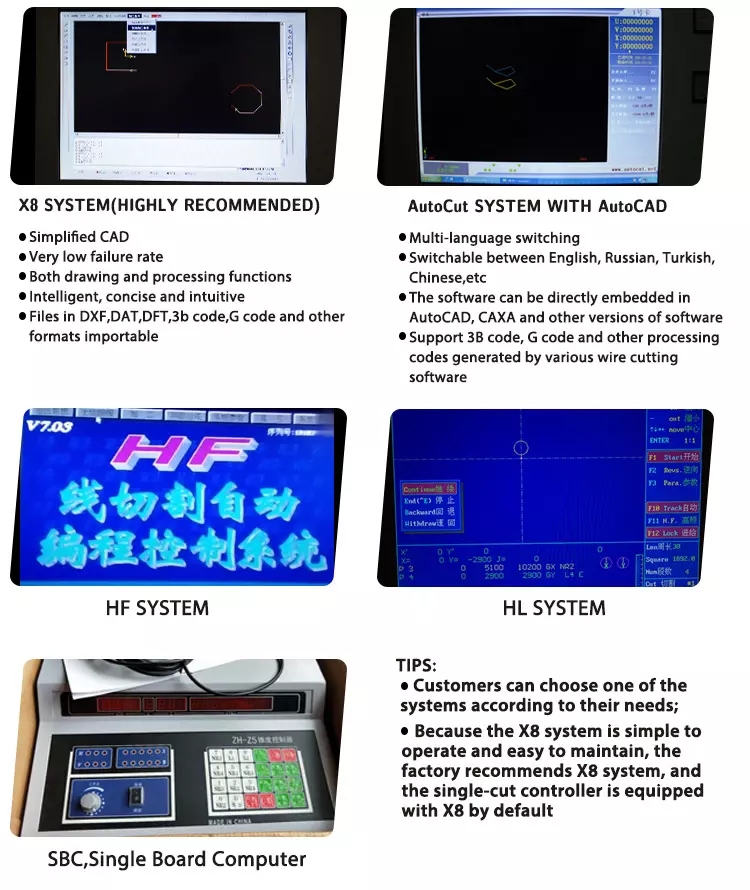

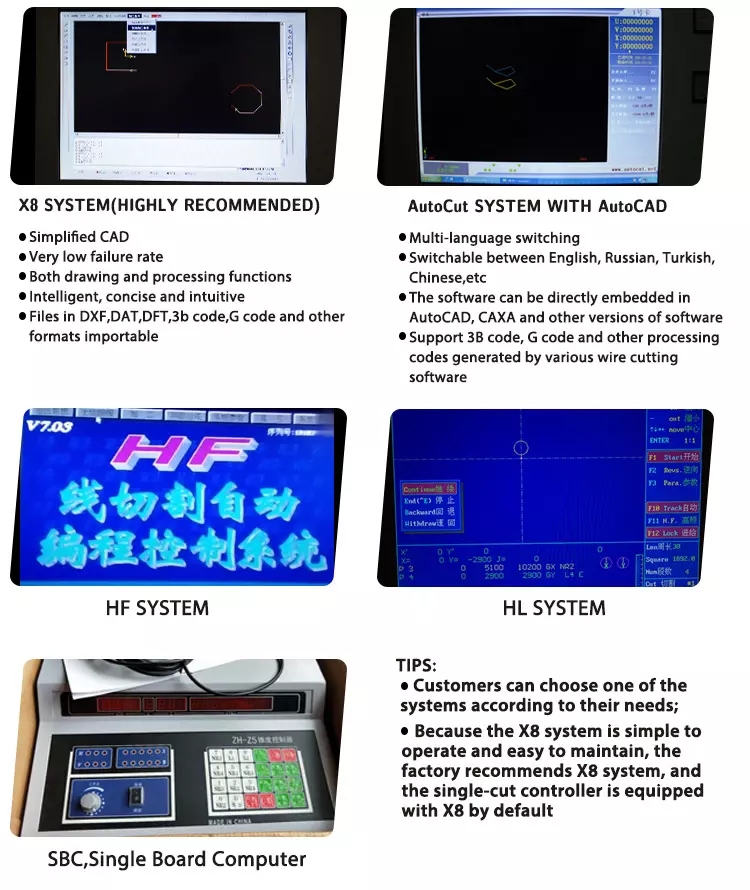

Software System Display:

Controller of the standard configuration

Single-pass (single-cut) controller

Standard system: X8 (Support multiple language switching)

Optional system: AutoCut, HL, HF

Optional controller

Semi-intelligent multi-pass (multi-cut) controller

Standard system: AutoCut with AutoCAD

Optional system: X8, HF

Fully intelligent multi-pass (multi-cut) controller

Standard system: AutoCut with AutoCAD

Equipped with intelligent expert parameter database and intelligent tracking function, the database can automatically generate cutting parameters

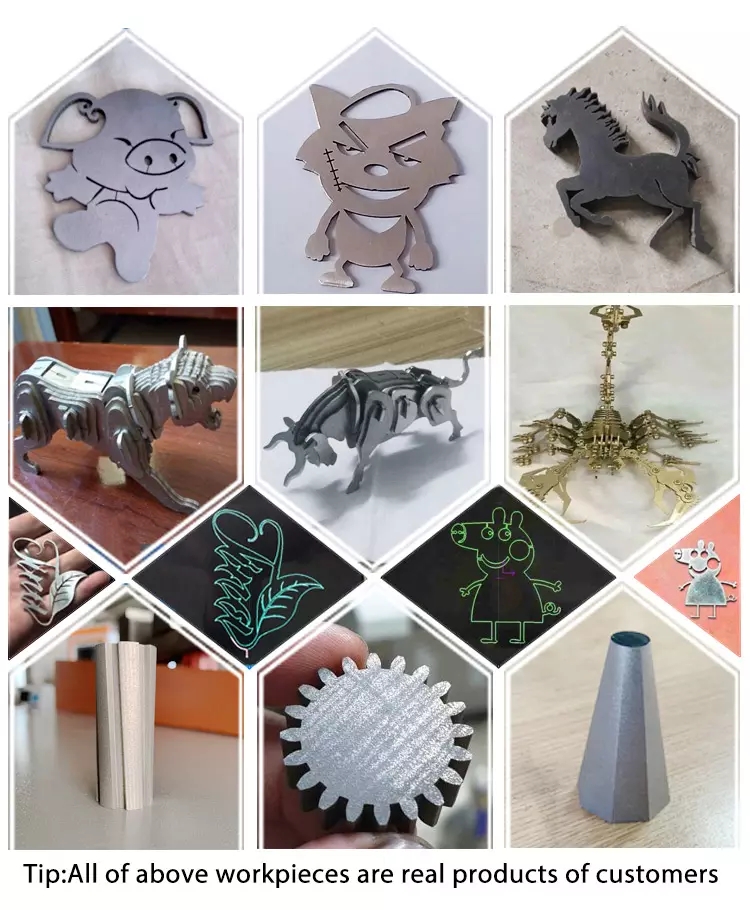

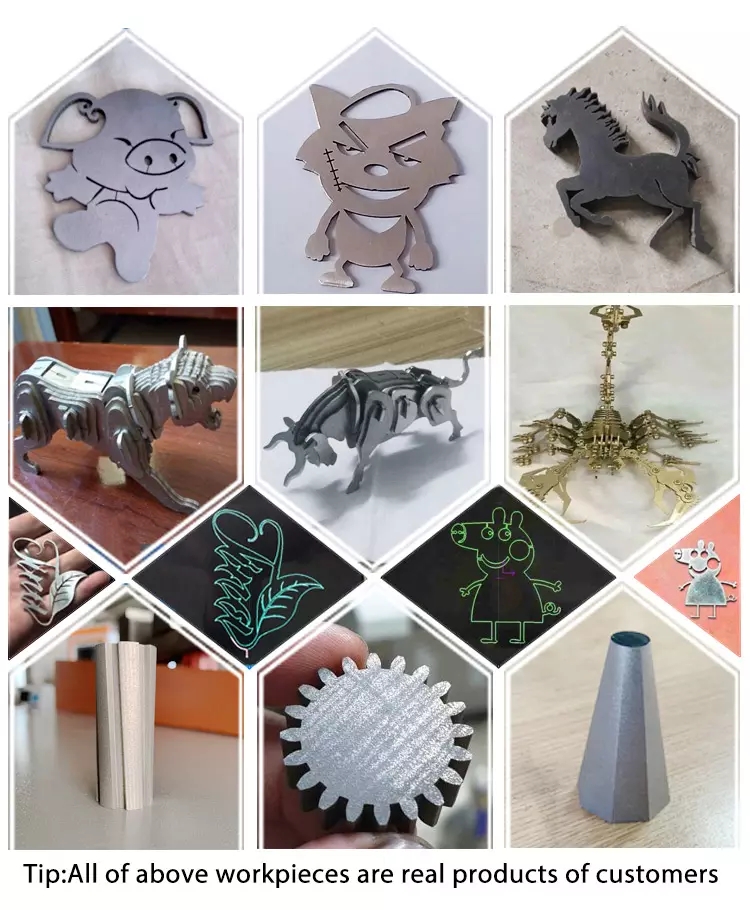

Workpiece show from real photos:

Taizhou Terui CNC Machine Co., Ltd. produces whole series of DK77 CNC EDM wire cutting machines, which adopts high precision V-shaped guide rail (Linear guide rail optional) and P3-grade high precision ball screw. The products have high quality, complete models, long service life and high precision. Machine specifications can be customized according to customer needs, like non-standard models DK7740(45)F, DK7750(55)F, DK7763F, DK7780F, DK77100F, DK77120F or even larger models. The company also produces ±30°, ±45° swing large taper machines and CNC high-precision middle speed EDM wire cutting machines (Precision ≤ ±0.005mm, roughness ≤ 1.0μm).

The following are the main parameters of DK77 series machines.

1、Standard maximum cutting taper:±6°/80mm; (±15°, ±30°, ±45° are optional)

2、Precision ≤ 0.02mm, according to GB7926-2005 standard; (If linear guide equipped, the precision can reach 0.01mm)

3、Best surface roughness ≤ Ra2.5μm (single-cut), Ra1.5μm (multi-cut);

4、Molybdenum wire diameter: 0.1-0.2mm;

5、Max. cutting speed ≥ 120mm^2/min;

6、Voltage: 3 phase 380V (single phase 220V, 3 phase 220V or other voltage can be customized), Power: 1.5KW;

7、Working fluid: Water-based emulsion.

Please go to high-speed-wire-edm.html to check the detailed model info. OR feel free to contact us to get a solution or quotation by email, WhatsApp or phone.

Email: daley@teruimachine.com, jack@teruimachine.com

Mobile/WhatsApp: +86 158 5087 0508, +86 173 1566 7380

Tel: +86-523-86816601

Software System Display:

Controller of the standard configuration

Single-pass (single-cut) controller

Standard system: X8 (Support multiple language switching)

Optional system: AutoCut, HL, HF

Optional controller

Semi-intelligent multi-pass (multi-cut) controller

Standard system: AutoCut with AutoCAD

Optional system: X8, HF

Fully intelligent multi-pass (multi-cut) controller

Standard system: AutoCut with AutoCAD

Equipped with intelligent expert parameter database and intelligent tracking function, the database can automatically generate cutting parameters

Workpiece show from real photos: